Project Description

Project Overview

The Gibbons HVAC team was tasked with upgrading and maintaining the HVAC system in a high-profile London court building, focusing on Air Handling Units (AHUs) and a fan gearbox on the roof. The project involved replacing AHUs in the probation area and the main plant room, as well as refurbishing a gearbox for fan no.4. Here’s a detailed account of the approach, execution, and outcomes.

Phase 1: AHU 3 Replacement

The project commenced with the replacement of AHU 3, the smallest unit serving the probation area. The steps involved were:

Isolation and Disconnection:

- We started by electrically isolating and disconnecting the power supply.

- The coil was isolated and drained to facilitate safe removal.

Removal of the Old Unit:

- The AHU was unbolted from the ductwork and removed.

- Due to its manageable size, it was lifted and skated out in one piece.

- Some ducting was also removed as it was incompatible with the new, slightly larger unit.

Installation of the New Unit:

- The new AHU was positioned on the slab with anti-vibration Tico pads underneath.

- Given its longer length, a support foot was fabricated to stabilize the overhanging part.

- New duct connections were made and fitted.

- The old pipework was cut back, and new connections were made to the new coil. This involved a pipe freeze to fit new isolation valves due to the absence of dedicated isolation valves.

- A new Danfoss 3-way valve and actuator were installed.

Final Connections and Testing:

- New cabling was run and connected to the fan.

- The unit was tested and operated perfectly without issues.

Phase 2: AHU 1 and AHU 2 Replacement

Following the successful installation of AHU 3, we proceeded to replace AHU 1 and AHU 2 in the main plant room. These steps were:

Removal of AHU 1:

- Similar to AHU 3, the electrical and water connections were isolated and disconnected, requiring a pipe freeze for new isolator valves.

- Due to its larger size (approximately 4 meters long), the unit was cut into manageable pieces for removal.

- The old unit was scrapped on-site.

Installation of the New AHU 1:

- The new unit arrived in four sections, designed to fit through the plant room doors.

- Each section was positioned on the concrete slab, aligned for proper ductwork fitting.

- The sections were sealed with special foam and bolted together to ensure an airtight seal.

Replacement of AHU 2:

- The process mirrored that of AHU 1, with the old unit cut up and removed.

- New sections were installed and bolted together.

Final Connections and Testing:

- New duct and pipe connections were made to the coils.

- Electrical connections were completed, and the fans were tested, confirming flawless operation.

Phase 3: Fan No. 4 Gearbox Refurbishment

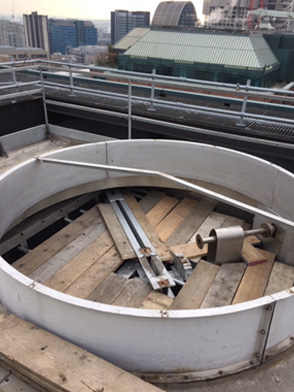

The final phase involved refurbishing the gearbox for fan no. 4 on the roof. The key steps were:

Preparation and Inspection:

- Arriving on site at 8 am, we signed in at security, received PTW and access passes, and proceeded to the Engie office for briefing.

- On the roof, scaffolders had erected a lifting frame across the fan to facilitate gearbox removal.

Gearbox Removal:

- The gearbox was drained of oil and the impeller unbolted for better access.

- It was discovered that the key from the gearbox end of the prop shaft had fallen out, causing damage to the gearbox shaft and coupling.

- The gearbox was unbolted, lifted out, and moved to the access hatch for removal.

Installation of Refurbished Gearbox:

- The refurbished gearbox was lifted into place using the lifting frame and bolted down.

- Oil lines were reattached, and the impeller was rebuilt.

- Due to the damaged coupling, the prop shaft was left off pending the arrival of a new coupling from the USA.

Conclusion

The failure to install a new coupling during the previous refurbishment led to wear and the eventual loosening of the key, causing significant damage to the gearbox shaft and coupling. A refurbished gearbox was successfully installed, and a new coupling has been ordered to complete the repair. The project demonstrated meticulous planning and execution, ensuring all HVAC units and components operated efficiently and reliably.