How does a centrifugal pump work?

Pumps make many aspects of work and life much easier, and whether you manage a water treatment works or are cleaning your car windscreen whilst driving, someone somewhere relies on the humble pump. But how exactly do pumps work?

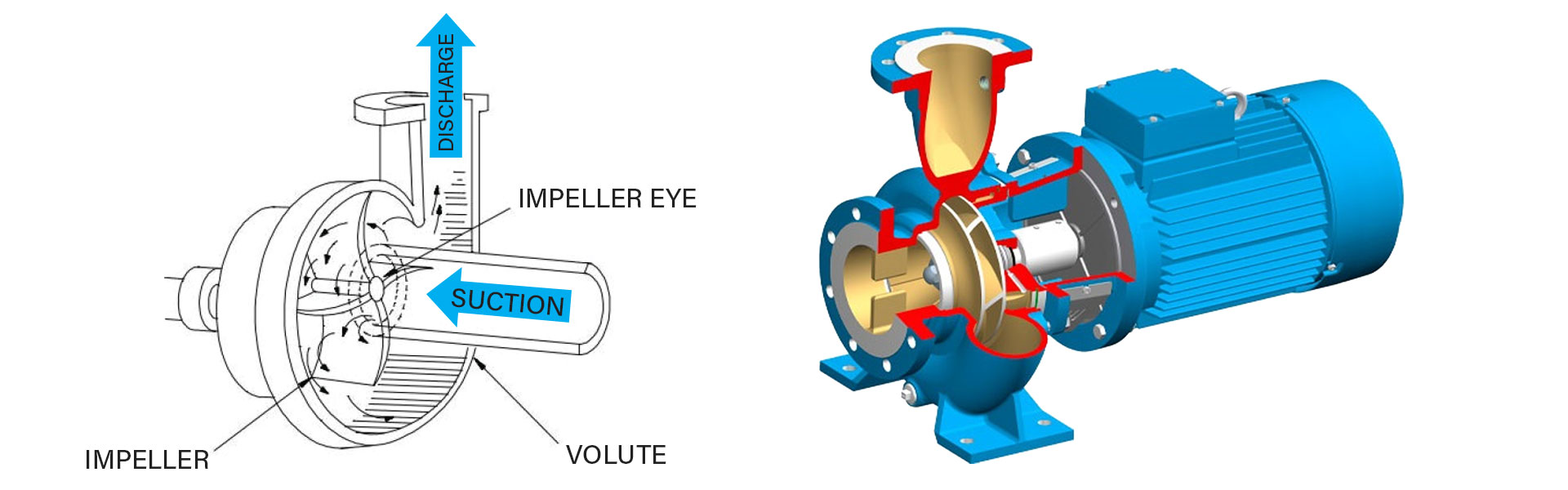

A centrifugal pump is basically made from housing that has an inlet and an outlet. The housing will have an impeller inside, and a motor or drive that’s job is to rotate the impeller. The pump’s casing is designed to create a gradually widening channel, known as the volute. When the motor or drive rotates the impeller, a centrifugal force is created.

The force created throws the liquid outward to the volute which creates a reduced pressure area at the eye of the impeller. This acts as a vacuum and provides a flow of liquid to the pump impeller. On the other side, the volute causes the liquid to slow down, and the pressure within the pump’s housing increases. The increase in pressure forces the liquid out of the discharge outlet and then into the piping system of the process.

Centrifugal pumps have the highest flow rates of all pump types and can be used to pump all kinds of liquids, including clean or dirty fluids, and those with low viscosity. They are commonly used as metering pumps to move precise volumes of liquid for treating drinking water, wastewater, boiler water, swimming pool water, and so on. They are regularly used in process applications where exact measurement of fluids is needed, which can be the production of anything from food to ready-mixed concrete.

Centrifugal pumps hold the advantage of having no drive seals, meaning the risk of leaks is eliminated. This allows hazardous liquids to be pumped without fear of spillage or seepage into the electric motor. In addition, because the pump chamber is separated from the electric motor by an air gap, there’s a thermal barrier and therefore no potentially damaging heat transfer can occur.

5 golden rules of centrifugal pump maintenance

Regular maintenance is essential for keeping your electro-mechanical equipment in the best possible order. Here are five top tips for centrifugal pump maintenance that will help ensure your equipment remains efficient and reliable.

- When aligning the pump with an electric motor, ensure the equipment is at operating temperature.

- Rotating components should be dynamically balanced to minimise vibration, which can lead to premature wear and equipment failure.

- Pipes must be properly arranged to avoid unwanted pressure or movement. If pipe strain is identified, it should be corrected without delay.

- Piping reducers must be properly fitted, otherwise air can enter the pump suction, increasing the risk of cavitation while reducing efficiency.

- Inspect mechanical seals and replace them if necessary.

If you’d like to properly maintain your pumps but lack the time or personnel to carry them out, let an experienced provider such as Gibbons take care of it for you.

We service, maintain and repair pumps of all sizes in the industrial, agricultural, and commercial sectors.

For more information, and a competitive quote, call us on 01621 868 138 or email info@gibbonsgroup.co.uk.

Photo by Magda Ehlers: https://www.pexels.com/photo/red-and-gray-industrial-machinery-2569842/