Project Description

When a major international financial institution wanted to improve indoor air quality (IAQ) at its 250,000-square feet central London commercial offices in order to comply with the WELL Building Standard™ and save energy, Gibbons Ultraviolet Solutions was commissioned to undertake the project.

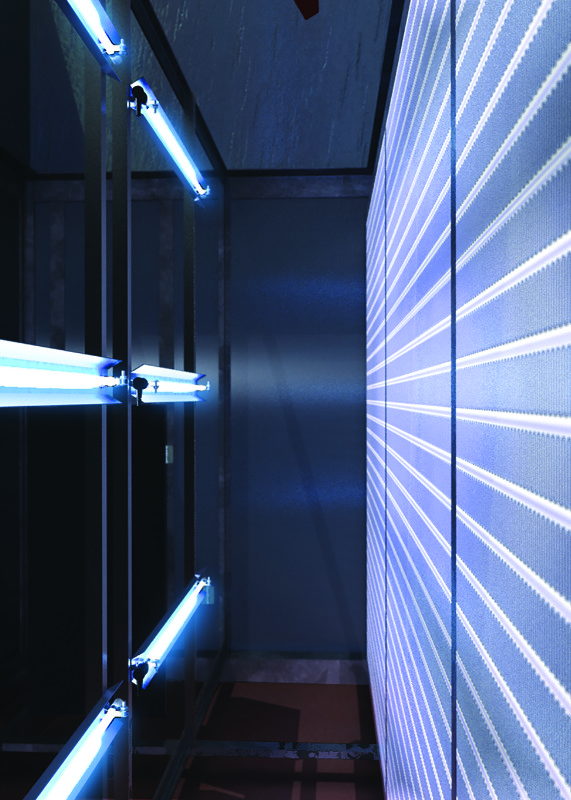

It was decided to install Gibbons’ CoilCare® ultraviolet germicidal irradiation (UVGI) air and surface disinfection system within the building’s air handling units (AHUs), with a view to eradicating contaminants and returning the equipment to its original operating condition.

The cooling coil of an AHU is a breeding ground for mould, viruses and bacteria, which form a slimy substance on the coil fins known as biofilm.

As well as reducing cooling coil efficiency by restricting thermal conductivity and therefore increasing energy consumption, biofilm contaminates the airstream which may jeopardise the health, wellbeing and productivity of building occupants.

CoilCare® uses powerful high-output ultraviolet-C (UVC) photoniser lamps to disinfect throughout the cooling coil by disrupting the biofilm’s DNA and eradicating it. The system is chemical free and requires minimal maintenance, with photonisers having an 18,000-hour service life. Continued use of our CoilCare® system prevents the re-growth of biofilm, maximises AHU performance and helps protect all building users.

The importance of the U-value

U-values measure a cooling coil’s thermal performance. The higher the value, the more efficient the operation. Prior to the installation of CoilCare®, a U-value of 8,587 w/m2K was recorded from the client’s cooling coil. The U-value after CoilCare was fitted was 12,169 w/m2K – an increase of 41.71%.

Results

Annual chilled water volume reduced from 28,849 to 18,507 tonnes – a reduction of 35.85%. Our client will enjoy annual savings of £2,116 for a single coil.

Surface sampling

Contact plate samples were taken from the face of the cooling coil, with the pictured sample (left) representing seven days’ growth.

Sixty days after the installation of two CoilCare® CCX 48 High-Output photonisers, this sample (right) proved that mould had been eliminated in line with expectations.

Outcomes

After installation and running costs, our client achieves net annual energy savings worth £1,633.

Return on investment on installation costs is calculated at two years and nine months.

Our client is satisfied that the installation of our CoilCare system has made a significant contribution to their drive towards WELL Building Standard™ certification.