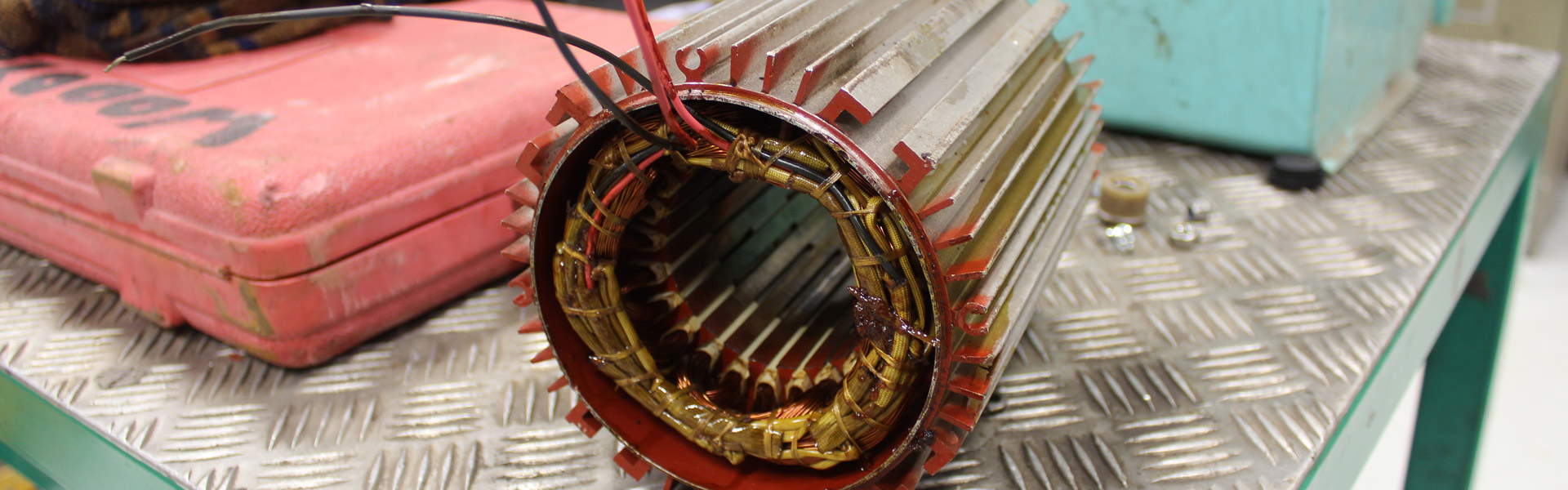

If the above photo looks like just another motor to you… look again!

You’re actually looking at the product of much hard work and dedication, and the very first motor rewind completed by our engineer Dave Knights!

Dave first joined us in spring 2018. Starting off in our Agricultural fans department, he came in at a busy time for the company and helped us stay on top of the demand for our best-selling grain fans.

Fast forward nearly two years and Dave can now be found in our rewinds and repairs workshop, where he has just completed his first motor rewind for a company that supplies laboratory products to companies all over the world.

We’re very lucky to have some highly experienced engineers in our workshops, so Dave has been trained up by Kevin Shakespeare, who has worked in the rewinds department here at Gibbons for over 25 years!

Starting from scratch, Dave completed the full rewinding process, from cutting out the old windings, to prepping the slots, to using a special machine to create new windings of the correct thickness and length.

After fitting the new windings, they were then varnished for protection and to hold them in place before the motor was cleaned up and fully tested.

“It is really satisfying to see the motor running at the end”, said Dave, who enjoyed the challenge of restoring the motor.

We’re looking forward to seeing what Dave restores next!

“I enjoy the challenge and it is really satisfying to see the motor running at the end” – Dave Knights, Gibbons Engineering Group